One of Rumblefish’s research areas is small swarms of underwater drones. It is a big part of why we are researching both ways to bring down the cost of drones, and ways to automate their construction. That same motivation also has us looking at just how small the drones we create can be. Out of that work came our BT series of thrusters.

One of the side benefits of flying drones taking off in popularity is that economies of scale have driven down the cost of their parts. Since the same brushless motors that flying drones use can be modified to run underwater, this trend has driven down the cost of making thrusters for underwater drones. As a result, there are already plans for several solid 3D printable thrusters available online. Most are offshoots of, or inspired by, Blue Robotics T100 thruster and use either an A2122 or DT700 (or similar) motor.

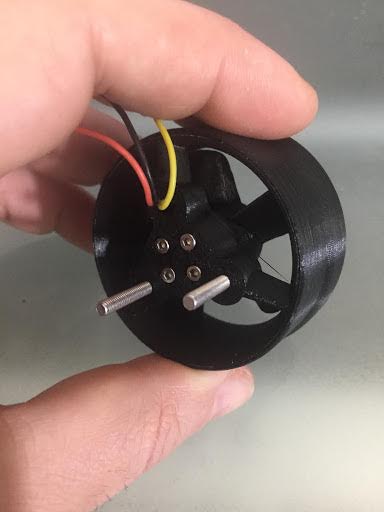

The new class of micro size drones also brought out new classes of incredibly small brushless motors. Our BT class of thrusters is a micro class of thrusters based on those motors. As an example, the picture here shows an A2122 next to an SE1102 used in our BT1495 thruster design. The other image shows just the BT cowl, which works with several of the 14mm diameter micro class motors, next a Blue Robotics T100 thruster.

Thruster Components

Here you can see the BT1495 thruster. Printable files required for its construction are available in the downloads section.

The BT thruster series was designed to be both affordable, and so that its construction is in reach of anyone with access to a 3D printer and some simple tools. Its design consists of two printed parts, a cowling meant to house a 14mm diameter brushless motor, and a propeller designed to match a specific height motor. Both the propeller and cowling bolt to the motor using two M2 bolt. Two M3 mounting bolds are used to mount the cowling onto either a support strut, or directly to the platform to which thrust is to be imparted.